Machining

Precision Machining

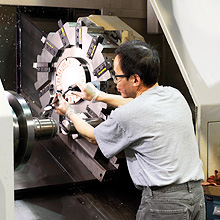

Some say that grinding is a lost art, but not at Stein Seal Company. We have over a dozen CNC cylindrical grinders capable of grinding diameters of over 24 inches. Grinding services, along with standard machine shop machining, are offered by our Company. Stein Seal is certified to ISO 9001:2015 and AS9100D, so you know that your parts will be made to the highest quality.

Off-shore machining operations are located in India, Mexico and the Czech Republic. All of these plants have achieved ISO and Aerospace Certification and have full scope machining capability. If you prefer you can contact our overseas plants directly, or you may work thru our home plant in Pennsylvania, USA. Machining capabilities of our overseas plants in turning, grinding, and lapping are from 3 inch to 16 inches diameter and for milling sizes 20 inch by 40 inch by 12” high can be machined. Our plants practice “Lean Manufacturing” with the use of manufacturing cells throughout our facilities. All components we produce are measured to verify dimensional requirements using computer controlled CMMs.

Our US manufacturing facilities are located outside of Philadelphia in three facilities that total over 215,000 square feet (20,000 square meters) and are located with our home engineering and executive offices. We produce many of the same products in our US operations as we do at our offshore facilities. This dual manufacturing capability provides you assurance that there is a back-up in the event of a disaster at one facility. In addition, we have the capacity to turn parts up to 56 inches in diameter and mill parts up to 60 inches long by 33 inches wide. Lapped flatness can be achieved on parts up to 48 inch diameter. We also are NADCAP approved for welding.

Stein Seal has invested heavily in mill-turning machines with dual chucks, which have proven to be highly efficient. More recently we have purchased Multi-Function machining centers with multiple pallets that can mill, turn, and perform 5-axis machining. These machines run untended 24 hours per day and parts to be machined can be loaded on pallets well before they are needed for machining. These machines are highly efficient and are helping to keep our costs competitive.

In addition to general machining, including grinding, Stein Seal offers superior product finishing capability. We are qualified for critical cleaning operations that include particle counting after cleaning when required. We also maintain a clean room with positive air flow which we use to make critical assemblies for aerospace, nuclear and other critical products.

Many products require hydrostatic pressure testing to verify the integrity of the product. Stein Seal is adept at testing set-ups that allow such testing. We also can dynamically test products in our state of-the-art dynamic testing facility.

When you are looking for a full-service supplier to manufacture your precision products, please give us a call. We can work with you and provide engineering support in addition to a quality product at a competitive price.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Aerospace Seals and Sealing Systems

Stein has developed an in-depth understanding of the extreme operating conditions to which seals used in the main shaft bearing sumps, gearboxes and generators in aircraft engines are subjected. Each precision sealing system is custom designed to perform flawlessly with low wear and long life. Our seals will withstand the wide range of conditions that will occur during normal operations including temperature extremes, high speeds and strong vibration.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Aerospace Seals and Sealing Systems

Stein has developed an in-depth understanding of the extreme operating conditions to which seals used in the main shaft bearing sumps, gearboxes and generators in aircraft engines are subjected. Each precision sealing system is custom designed to perform flawlessly with low wear and long life. Our seals will withstand the wide range of conditions that will occur during normal operations including temperature extremes, high speeds and strong vibration.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

BLOG

Space Tech Expo 2023 Conference Trade Show

Come visit Stein Seal at the 2023 Space Tech Expo and Trade show. Contact Russ Candell for info or to plan your meeting with Stein Seal in advance. Email RJC@steinseal.com Click on the link below for more information.... Space Tech Expo 2023 Conference Trade...

Aerospace

Aerospace Blog

Stein Seal now accepts all major credit cards through PayPal.

Markets

- Aerospace

- Industrial

- Marine

- Nuclear

- Power Generation

- Process Industry

Products

- Circumferential Seals

- Face Seals

- Brushing Seals

- Bellows Seals

- Film Riding Seals

- API 682 Seals

- Digital Static Tester

- Brochures

Services

- Machining

- Repairs

- Testing

![]() Stein Seal® Company

Stein Seal® Company

1500 Industrial Boulevard

Kulpsville, PA 19443-0316

Email: sales@steinseal.com

Tel: +1 215-256-0201

Fax: +1 215-256-4818

STEIN SEAL®, NOTHING MUCH GETS PAST OUR SEALS®, HYDROVENT®, HYDROLOAD®,

![]() are registered trademarks of the Stein Seal Company.

are registered trademarks of the Stein Seal Company.

Copyright ©2020 Stein Seal Company. All rights reserved.